Blogs

Don't forget to read some blogs!

WE ARE NOT A FAMILY IN THE COMPANY!

Of course, we are a team at work; We are not family.

We have a vision and a mission or a purpose and we can communicate on these grea...

B2B MARKETING AND SALES DICTIONARY

A To Z B2B marketing and sales terms that may help to your sales process.

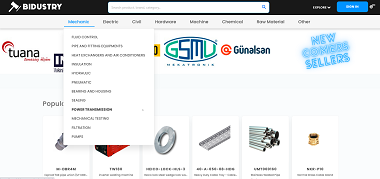

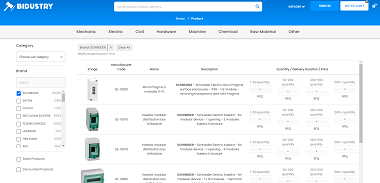

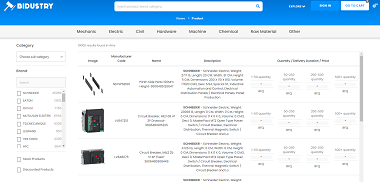

MoreBIDUSTRY: A PLATFORM TO REACH INDUSTRIAL MANUFACTURERS AND SUPPLIERS!

Procurement teams in companies have been searching for industrial products online for many years.

The Internet is very important for sou...

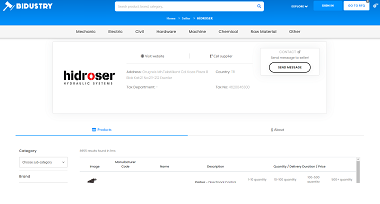

MoreARE YOU AN INDUSTRUAL MANUFACTURER OR SUPPLIER? HERE'S HOW TO GET STARTED AT BIDUSTRY:

Bidustry is a B2B marketplace for industrial sellers and buyers. Industrial manufacturers and suppliers serving products at Bidustry.

It...

MoreCOMPARISON OF YOUR COMPANY WEBSITE AND BIDUSTRY AS AN INDUSTRIAL B2B MARKETPLACE

Serving products on your own website?

The point is that is inbound marketing. SEO is one of the inbound marketing strategies.

In...

MoreBIDUSTRY IS CHANGING THE WAY B2B MARKETPLACE WORKS

Companies have been searching for platforms to reach potential customers besides their websites in the last 5 years. The Pandemic also sped up t...

MoreWHY DO MANUFACTURERS AND SUPPLIERS NEED THE INDUSTRIAL B2B MARKETPLACE: BIDUSTRY!

Inbound marketing is so important for B2B working companies. The key point is the distribution of contents and resources.

MoreBUILDING BRIDGES TO YOUR COMPANY WITH B2B MARKETPLACES AND OTHER METHODS

Today most companies have been struggling to reach leads. On the other hand, the internet is a good way to reach leads.

There are differ...

MoreA GUIDE TO SET UP & OPTIMIZE A BUYER PROFILE ON INDUSTRIAL B2B MARKETPLACE: BIDUSTRY!

Bidustry is B2B marketplace for industrial sellers and buyers!

Buyers are mostly factories, plants, refineries, industrial facilities, b...

MoreLOOKING TO BUY CHEMICAL GOODS? RFQ NOW ON BIDUSTRY! TOP 20 OF DECEMBER 2022

Looking to buy chemical goods! RFQ now on Bidustry! What are top 20 chemical goods of December 2022?

Before starting you should be aware...

MoreA GUIDE TO SET UP & OPTIMIZE A SELLER PROFILE ON INDUSTRIAL B2B MARKETPLACE: BIDUSTRY!

Bidustry is B2B marketplace for industrial sellers and buyers. There are two types of goods:Industrial and consumer...

MoreWHAT ARE DEMAND GENERATION METRICS?

The purpose of Demand Generation is to increase potential customer awareness through brand awareness.

Let's consider the awareness level...

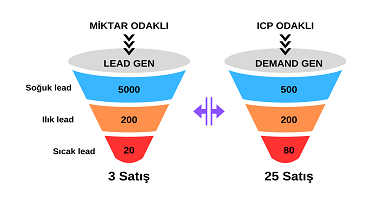

MoreDIFFERENCES BETWEEN LEAD GENERATION AND DEMAND GENERATION

Differences between Lead generation and Demand generation:

1- LEAD GENERATION focused on quantity. DEMAND GENERATION focused on targeted...

MoreCREATE A LONG-TERM PLAN FOR YOUR COMPANY!

You want to create a long-term road map for your company. You want to set up a system. Do you want to be sustainable?

A damage assess...

SUSTAINABLITY COMES FROM MARKETING MINDSET!

You cannot be sustainable without a marketing mindset in your company. Marketing is mindset not only operation.

Your system is consta...

MANUFACTURING OR MARKETING SELLS?

It is an accepted misconception that production, in particular, will increase sales on its own rather than marketing.

In fact, manufa...

IT IS NOT DIGITAL MARKETING VS TRADITIONAL MARKETING!

Digital marketing VS. traditional marketing is not right!

For example:

Pops (pop up/under) are digital but outbound market...

HOW DO YOU SET YOUR SALES GOALS?

So how do you set your sales goals?

Of course, you check your company memory! CRM. Do you?

It's better if you use CRM, but...

ARE YOUR WEBSITE COPY GOOD ENOUGH?

You've purchased or created a website template and are trying to fill in the blanks.

Copywriting in marketing is not like that. It's ...

YOU CAN'T BE EVERYTHING TO EVERYONE!

You can't be everything to everyone!

We can supply everything. We can produce anything! We solve everything for you. We are the solut...

CONTENT DISTRIBUTION ON SOCIAL MEDIA-1

In B2B, creating and distributing content on social media is an issue.

There are many blogs, posts, recommendations, recipes, etc. re...

SALES FUNNEL VS FLYWHEEL SHORT DEFINITION

It is a fact that the basis of all healthy growth companies we see today, as a case study, is word of mouth marketing (WoM), triggered by happy ...

MoreWHAT IS BUYER ENABLEMENT?

"Buyer enablement"

Most people around the global still struggling about what are lead, prospect, Opportunity? While focusing on these...

Differences between lead generation and demand generation-1

Demand generation VS lead generation may seem a bit confusing.

More6 TIPS TO INCREASE YOUR LEADS FROM INBOUND SOURCES & HOW TO USE BIDUSTRY IN THIS WAY!

B2B working companies have annual sales goals. In the last ten years some of those companies started to have sales goals upon internet. They mos...

More1-BENEFITS OF USING A B2B MARKETPLACE FOR MANUFACTURERS AND SUPPLIERS!

Today manufacturers and suppliers have been searching platforms to start healthy marketing and sales activities.

More

A COMPARISON OF TRADITIONAL SOURCING METHODS VERSUS USING A B2B MARKETPLACE!

For many years, people in companies have been trying to reduce costs of time and money. When you think about companies, their purchasing is not ...

MoreDIFFERENCES BETWEEN MARKETING, SALES AND BUSINESS DEVELOPMENT

Today, businesses offer their products and services to potential customers through models such as B2B, B2C, C2C. Businesses create strategies at...

MoreB2B LEAD GENERATION IN PANDEMIC WORLD

With the pandemic, companies have turned to technology tools in finding potential customers. E-commerce showed a different increase in 2020 comp...

MoreWHAT ARE DIFFERENCES BETWEEN B2B, B2C AND C2C MARKETPLACES?

With the development of technology, sellers turned to marketplaces in order to reach buyers using search engines. Marketplaces have gained...

MoreMANUFACTURING AND PURCHASING IN INDUSTRIAL FACILITIES

Industrial product, consumption product, etc. products are delivered to the customer as a result of different production types according t...

MoreDEVELOPMENT OF PROCUREMENT AND NEW TRENDS

The purchasing process differs in various product categories. When examining according to product categories, 2 concepts come to the fore...

MoreWHAT IS PROCUREMENT? WHAT ARE MAIN PROBLEMS?

Procurement is simply the acquisition of materials and services from product sellers or service providers on a specified schedule. As an individ...

MoreB2B MARKETPLACE IN DIGITALIZATION

What is the marketplace?

Marketplace is a platform that allows businesses or consumers to trade globally or loca...

MoreDIFFERENCES BETWEEN COLD CALL AND TELEMARKETING

There are differences between Cold Calling and Telemarketing. What are they?

1- The purpose of Cold Calling is to continue the conver...

DIFFERENCES BETWEEN INDUSTRIAL GOODS AND CONSUMER GOODS

Consumer products are goods that are used to meet daily needs and are mostly preferred on an individual basis. Usually they are low purchasing a...

MoreWHAT IS INBOUND MARKETING? HOW CAN BIDUSTRY HELP?

Inbound marketing is about creating marketing and sales that people love by providing helpful content and resources that attract people to you a...

MoreLOOKING TO BUY MECHANICAL PARTS! WHAT ARE TOP 20 DECEMBER 2022?

Looking to buy mechanical parts! RFQ now on Bidustry! What are top 20 mechanical goods of December 2023?

MoreTHE POTENTIAL OF CROSS-BORDER TRADE AND ADVANTAGES WITH A B2B MARKETPLACE

For many years, people in companies have been exploring about trading cross-border and increasing brand awareness globally.

When you thi...

MoreINBOUND MARKETING vs. OUTBOUND MARKETING FOR COMPANIES!

For many years, marketing has been changing it’s form and coming us within different ways. The internet has also become a key actor in the...

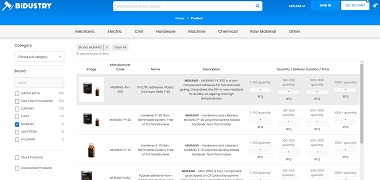

MoreLOOKING TO BUY ELECTRICAL PARTS? RFQ NOW ON BIDUSTRY!: TOP 20 ELECTRICAL GOODS OF DECEMBER 2022

Looking to buy electrical parts? RFQ now on Bidustry!: Top 20 electrical goods of the last month, you can find on Bidustry.

Sellers are ...

MoreB2B MARKETPLACE FOR INDUSTRIAL SELLERS AND BUYERS?

B2B marketplace for industrial sellers and buyers? Whaaat?!

There are 10 million factories around the world. In addition to this, constr...

MoreB2B E-COMMERCE MAY NOT BE WHAT YOU THINK!

If you are an industrial goods manufacturer or a supplier, e-commerce may not satisfy your expectations.

E-commerce (electronic commerce...

MoreDO YOU HAVE UNLIMITED PAID ADS BUDGET FOR YOUR COMPANY?

Do you have unlimited paid ads budget for your company?

Maybe you are performance marketing addicted?

The truth is most companie...

MoreWHAT ARE 3 BENEFITS OF MARKETPLACES? WHICH ONE IS FIT FOR YOU?

What are 3 benefits of marketplaces? How can we decide which one is fit for us?

Most marketplaces offer 3:

-To Increase br...

MoreDIGITALIZATION AND PURCHASING DURATION

Today, businesses adopt themselves to the digitalization by investing in social media, cloud technologies and big data so as to build a connecti...

MorePROJECT PLANNING AND MANHOUR, COST CALCULATION IN INDUSTRIAL FACILITIES

Industry sector has been following major contract projects which are succesfully signed by construction companies in recent years. Those c...

MoreELECTRICAL AND INSTRUMENTATION INSTALLATION PERIOD IN INDUSTRIAL FACILITIES

An industrial facility means a facility engaged in activities such as an agriculture, a forestry, a fishing, a mining, a production, a transport...

MoreSMALL DICTIONARY THAT CONTAINS INDUSTRIAL TERMS

You may check mini industrial terms dictionary. It includes industrial terms.

MoreDIFFERENCES BETWEEN PROCUREMENT AND PURCHASING

Companies have developed various methodologies so as to provide themselves optimum material and service from the past to present. These methodol...

More6 TECHNOLOGICAL INNOVATIONS FOR INDIRECT PURCHASING

Since 2011, indirect expenses have increased by 7% per year, according to Mckinsey & Company. Despite this rate, companies find it difficult...

MorePURCHASING AND BIDUSTRY IN PANDEMIC WORLD

The corona virus has affected industrial electrical, mechanical and civil product suppliers such as exporters, distributors, and retai...

MoreCATEGORY MANAGEMENT WITH BIDUSTRY IN INDUSTRIAL PRODUCTS

Bidustry is a B2B marketplace for industrial product sellers and buyers.

There are 2 types of products:

Manufacturer goods...